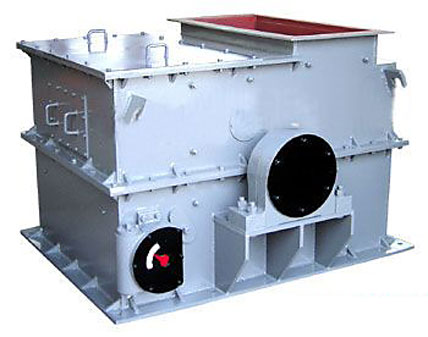

PCH1010 Hammer Crusher

HomeProducts Center

- Mine Car & Construction Truck

- Belt Conveyor

- Scraper Conveyer

- Rock Loader

- Scraper Rock Loader

- Coal Mining Machine

- Road header

- Mine Car Dumper

- Shaking Table,Car Pusher

- Detritus Equipment

- Drilling Equipment

- Mine Drilling Machine

- Drilling Rod,Drilling Bits

- Water well drilling rig

- Rail Arrester

- Rail Transit Equipment

- Railroad tie

- Railway Maintenance Tools

- Railway Parts

- Track Switch

Large Equipment

Transportation Equipment

Supporting Equipment

Lifting Equipment

Guniting Equipment

Chemical Equipment

Mine Door

Rock Drilling Equipment

Ventilation&Guard Equipment

Safe&Protection Instrument

Pumping Equipment

Steel Products

Railway Materials

Explosion Proof Instrument

Electric Motor

Instrument And Meter

PCH1010 Hammer Crusher

Other Names:

The PC hammer crusher crushes by the collisions between high-speed hammer and material, which features in its simple structure, high reduction ration, high efficiency, ect.. The PC hammer crushers were developed for the both dry and wet crushing of brittl

Related Products- chris@bstvehicle.com

- 0537-7768777

- Please Leave a Message

Product Detail:

Product Introduction

Product Introduction

The PC hammer crusher crushes by the collisions between high-speed hammer and material, which features in its simple structure, high reduction ration, high efficiency, ect.. The PC hammer crushers were developed for the both dry and wet crushing of brittle, medium-hard materials for the mining, cement, coal, metallurgic, construction material, road building, and Petroleum & Chemical industries.

Main Characteristics

The hammer crusher is one of the main equipment for intermediate and fine crushing the brittle materials with less than intermediate such as limestone coal and other used in metallurgy, building material, chemical and water - power industry, with a feature of big crushing ratio and even product graininess.

Operating Principle

When materials get into crusher, first they are broken by the impact of ring hammer with high-speed rotation of the rotor. At the same time, the broken materials get power from ring hammer, and crush toward broken plate, being broken for the second fragmentation. Then they fall on the sieve plate, where they are further broken because of shear, extrusion, grind by ring hammer and interaction between materials. At last, they are discharged through the sieve pores. Sundries that can't be broken are put into metal collector and periodically removed.

Main Advantage

1.Simple structure design, large crushing ratio and high production efficiency.

2.It is highly efficient and energy saving, and causes low noise and little dust.

3.The space between grid sections can be adjusted to change discharging granularity in line with clients' needs.

4.The alloy hammerhead has excellent corrosion resistance and its service life is 1.5~2 times that of normal high manganese steel.

Technical Parameters

|

Model |

Feeding size(mm) |

Output size(mm) |

Capacity(t/h) |

Rotor speed(r/min) |

Motor power(kw) |

Weight(t) |

|

PCH0402 |

≤200 |

≤ 30 |

8-12 |

960 |

5.5kw |

0.8 |

|

PCH0404 |

≤ 200 |

≤ 30 |

16-25 |

970 |

11 |

1.05 |

|

PCH0604 |

≤ 200 |

≤ 30 |

22-33 |

970 |

15 |

1.43 |

|

PCH0606 |

≤ 200 |

≤ 30 |

30-60 |

980 |

30 |

1.77 |

|

PCH0808 |

≤ 200 |

≤ 30 |

70-105 |

740 |

45 |

3.6 |

|

PCH1010 |

≤300 |

≤ 30 |

160-200 |

740 |

90 |

6.1 |

|

PCH1016 |

≤300 |

≤ 30 |

300-350 |

740 |

155 |

9.2 |

|

PCH1216 |

≤350 |

≤ 30 |

620-800 |

740 |

355 |

15.0 |

|

PCH1322 |

≤400 |

≤ 30 |

800 |

595 |

400 |

24.9 |

Product Feedback

History Feedback: (0)

Latest Feedback