PCD Hammer Crusher

HomeProducts Center

- Mine Car & Construction Truck

- Belt Conveyor

- Scraper Conveyer

- Rock Loader

- Scraper Rock Loader

- Coal Mining Machine

- Road header

- Mine Car Dumper

- Shaking Table,Car Pusher

- Detritus Equipment

- Drilling Equipment

- Mine Drilling Machine

- Drilling Rod,Drilling Bits

- Water well drilling rig

- Rail Arrester

- Rail Transit Equipment

- Railroad tie

- Railway Maintenance Tools

- Railway Parts

- Track Switch

Large Equipment

Transportation Equipment

Supporting Equipment

Lifting Equipment

Guniting Equipment

Chemical Equipment

Mine Door

Rock Drilling Equipment

Ventilation&Guard Equipment

Safe&Protection Instrument

Pumping Equipment

Steel Products

Railway Materials

Explosion Proof Instrument

Electric Motor

Instrument And Meter

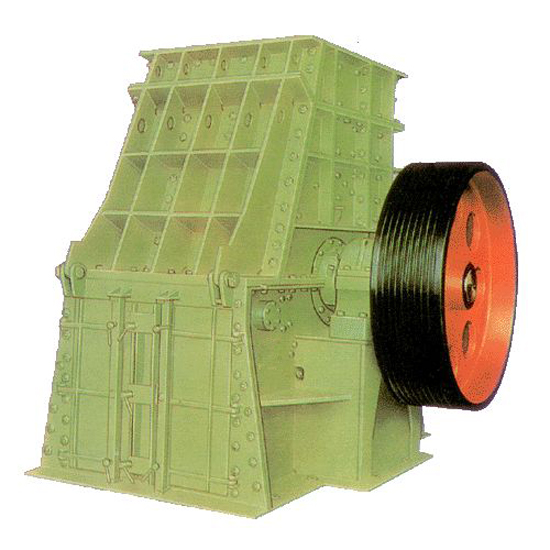

PCD Hammer Crusher

Other Names:

This series feature of rational multi crushing chambers and novel double adjusting mechanism, which can ensure 85% of the discharged materials less than 3mm, and the uniformity of the product fineness can be controlled. Easy access for maintenance has ma

Related Products- chris@bstvehicle.com

- 0537-7768777

- Please Leave a Message

Product Detail:

Product Introduction

Product Introduction

This series feature of rational multi crushing chambers and novel double adjusting mechanism, which can ensure 85% of the discharged materials less than 3mm, and the uniformity of the product fineness can be controlled.

Easy access for maintenance has made the hammers and screen bars replaced much easier. All the wearing parts are made of new type of high chromium alloy materials with multiple elements so as to ensure the abrasive property and impact-resisting property of hammers and liner plates. This series of crushers also feature of stable operation. low dust and less power consumption which have prestigious advantages when comparing with conventional crushers.

Main Characteristics

1.Super-fineness crushing capability: The new particles size adjusting mechanism guarantees 85% of the particles controlled within 3mm.

2.High-efficient and energy-saving: 40% power consumption reduced at equivalent output.

3.Extra long life: hammer heads are made of new type of high quality alloy materials with multiple elements and can be turned for use thus to prolong the service life by 4times.

4.Great crushing ration: incorporating primary, secondary crushing for clinkers, secondary and tertiary crushing for limestone into one step.

5.Easy Maintenance: The rear cover of the upper machine frame can be hydraulically (hand)-opened to make the maintenance much easier.

Operating Principle

The main parts of efficient compound crusher is rollers with hammer,the rollers consists of main shaft,sphere plate, axis roll and hammer. Motor drived roller in high speed running inner the crushing champer, the materials be send from top into the crusher,by the striking,impacting,shearing and grinding into power.At the roller buttom is a screen plate,it is used to collecting the materials whose size bellow the size of the screen plate,those size is bigger than the screen gap will be regrinded by the hammer,finally discharged from the discharging opening.

Technical Parameters

Product Feedback

History Feedback: (0)

Latest Feedback