MS Buried Scraper Conveyor

HomeProducts Center

- Mine Car & Construction Truck

- Belt Conveyor

- Scraper Conveyer

- Rock Loader

- Scraper Rock Loader

- Coal Mining Machine

- Road header

- Mine Car Dumper

- Shaking Table,Car Pusher

- Detritus Equipment

- Drilling Equipment

- Mine Drilling Machine

- Drilling Rod,Drilling Bits

- Water well drilling rig

- Rail Arrester

- Rail Transit Equipment

- Railroad tie

- Railway Maintenance Tools

- Railway Parts

- Track Switch

Large Equipment

Transportation Equipment

Supporting Equipment

Lifting Equipment

Guniting Equipment

Chemical Equipment

Mine Door

Rock Drilling Equipment

Ventilation&Guard Equipment

Safe&Protection Instrument

Pumping Equipment

Steel Products

Railway Materials

Explosion Proof Instrument

Electric Motor

Instrument And Meter

MS Buried Scraper Conveyor

Other Names:

Product Detail: Product Introduction MS scraper conveyor is a kind of buried scraper conveyer. It is a rectangular cross section in a closed shell, by means of a moving end of the scraper chain conveyor dust, small particles and small piece of bulk mate

Related Products- chris@bstvehicle.com

- 0537-7768777

- Please Leave a Message

Product Detail:

Product Introduction

Product Detail:

Product Introduction

MS scraper conveyor is a kind of buried scraper conveyer. It is a rectangular cross section in a closed shell, by means of a moving end of the scraper chain conveyor dust, small particles and small piece of bulk materials such as continuous delivery device, as in the transportation of materials. The scratch plate chain among all buried in the material, so it is called " Buried scraper conveyer''.

Main Characteristics

Simple structure,lower weight,small volume,fine seal, and it is convenience to instal and maintain.It can not only levelly transfer but also aslope or straightly transfer; It is allowed to feed and unload at either port, and process arrangement of the conveyer is flexible. Because the shell is closed, the result to improve workers’operating conditions and to prevent environment pollution is very outstanding when transferring floatable,poisonous,explosive and high-temperature materials.

Operating Principle

Materials are pressed by scraper chain in the movement direction and materials self weight when conveying horizontally, which generates internal friction. This friction assures steady state between batch layers and can sufficiently overcome external friction which materials moving generates in the groove, which make materials form constant and integral flow to be conveyed. Materials are pressed by scraper chain in the movement direction when vertically lifting, which generates side presure in the transverse direction to form inner friction. Meanwhile upper materials are shifted constantly by domn materials for constant feeding of down level section. This friction and shift can sufficiently conquer external friction which materials moving generates in the groove and self weight to make materials form constant and integral flow to be conveyed.

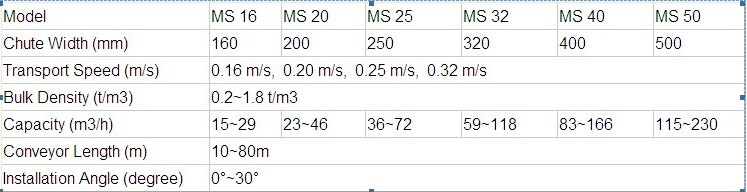

Technical Parameters

Product Feedback

History Feedback: (0)

Latest Feedback