MC Series Scraper Conveyor

HomeProducts Center

- Mine Car & Construction Truck

- Belt Conveyor

- Scraper Conveyer

- Rock Loader

- Scraper Rock Loader

- Coal Mining Machine

- Road header

- Mine Car Dumper

- Shaking Table,Car Pusher

- Detritus Equipment

- Drilling Equipment

- Mine Drilling Machine

- Drilling Rod,Drilling Bits

- Water well drilling rig

- Rail Arrester

- Rail Transit Equipment

- Railroad tie

- Railway Maintenance Tools

- Railway Parts

- Track Switch

Large Equipment

Transportation Equipment

Supporting Equipment

Lifting Equipment

Guniting Equipment

Chemical Equipment

Mine Door

Rock Drilling Equipment

Ventilation&Guard Equipment

Safe&Protection Instrument

Pumping Equipment

Steel Products

Railway Materials

Explosion Proof Instrument

Electric Motor

Instrument And Meter

MC Series Scraper Conveyor

Other Names:

Product Detail: Product Introduction MC scraper conveyor a kind of buried scraper conveyer. It is a rectangular cross section in a closed shell, by means of a moving end of the scraper chain conveyor dust, small particles and small piece of bulk materia

Related Products- chris@bstvehicle.com

- 0537-7768777

- Please Leave a Message

Product Detail:

Product Introduction

Product Detail:

Product Introduction

MC scraper conveyor a kind of buried scraper conveyer. It is a rectangular cross section in a closed shell, by means of a moving end of the scraper chain conveyor dust, small particles and small piece of bulk materials such as continuous delivery device, as in the transportation of materials. The scratch plate chain among all buried in the material, so it is called " Buried scraper conveyer''.

Applicable Scope

MC scraper conveyor is widely used in chemical, machinery, metallurgy, light industry, food, medicine, transportation, utilities and other departments. It is used to transport the dust-like, small granular materials and small block.

Main Characteristics

1. Totally enclosed structure, light weight, small volume.

2. Convenient installation and maintenance.

3. Horizontal or slightly inclined transport from 0°to 30.

4. Multiple material feeding point and discharging point.

5. Conveying distance is up to 80m with material temperature lower than 120°C.

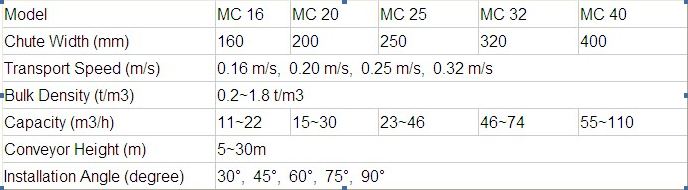

Technical Parameters

Product Feedback

History Feedback: (0)

Latest Feedback